Understanding the Process of Hydraulic Cylinder Honing

Hydraulic cylinder honing is a specialized machining process designed to achieve a high level of precision and surface finish on the inner bore of hydraulic cylinders. This meticulous technique plays a crucial role in maintaining the optimal functionality and longevity of hydraulic systems.

The Hydraulic Cylinder Honing Process

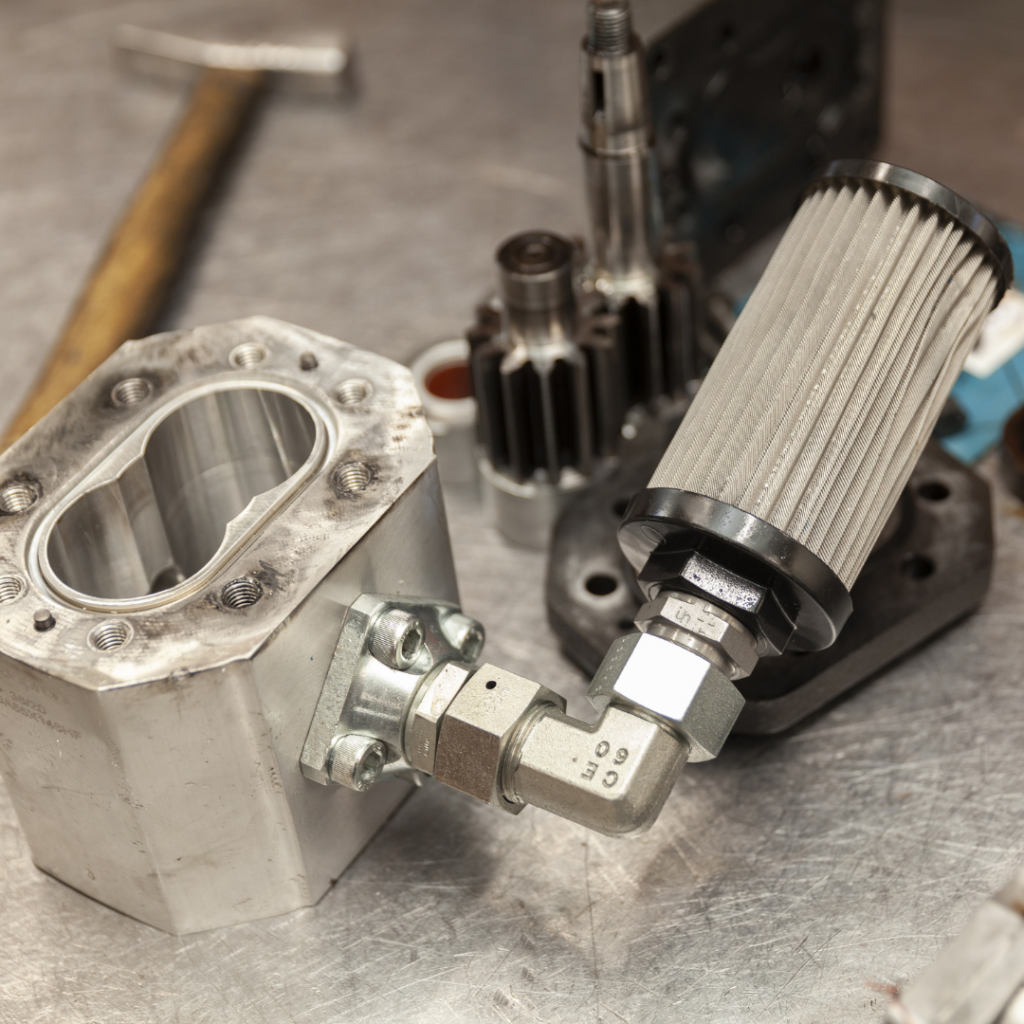

Preparation

Before honing begins, the hydraulic cylinder is disassembled, and the piston and other internal components are removed. This allows access to the inner bore, which is the focus of the honing process.

Initial Inspection

The inner surface of the hydraulic cylinder bore is closely inspected for any imperfections, such as scratches, scoring, or irregularities. This assessment helps determine the extent of honing required.

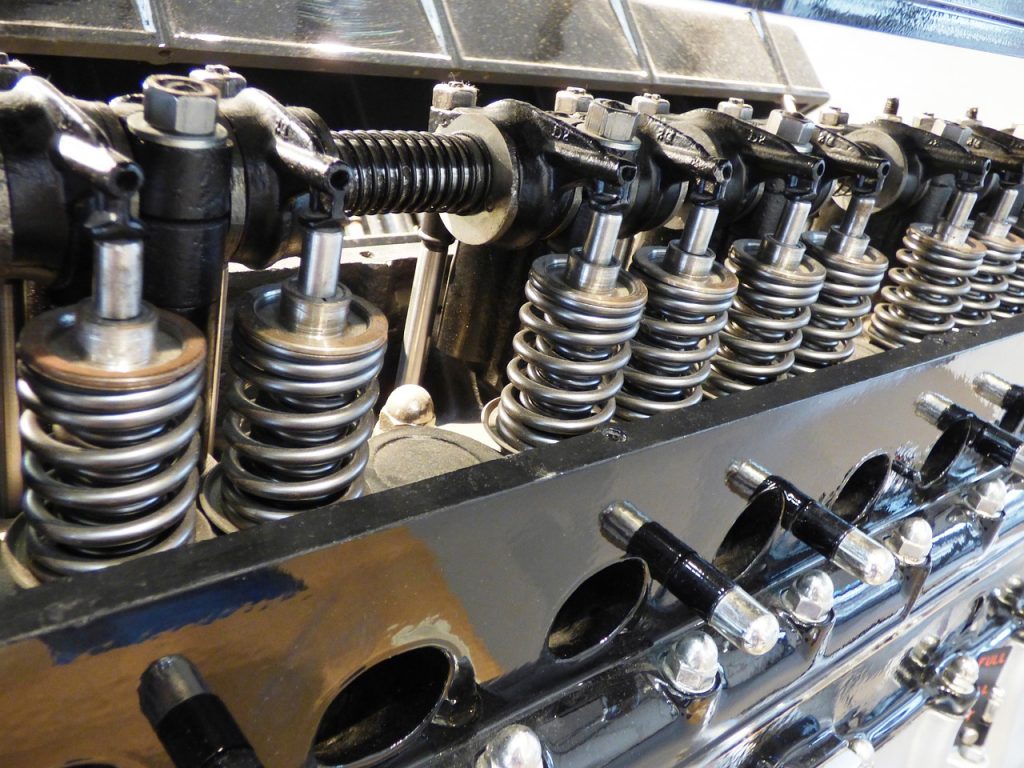

Honing Tool Selection

The honing tool is carefully selected based on the specific requirements of the hydraulic cylinder. Various honing tools, such as abrasive stones or diamond-plated tools, may be chosen depending on the material of the cylinder and the desired surface finish.

The Hydraulic Cylinder Honing Process

Once the tool is inserted into the hydraulic cylinder, the honing process begins. The tool oscillates or rotates while moving in and out of the cylinder bore. This controlled movement helps remove material evenly, resulting in a smooth and precisely finished inner surface.

Achieving the Desired Surface Finish

Honing aims to achieve a specific surface finish, measured in terms of roughness. The honing process helps eliminate imperfections, creating a surface that promotes efficient sealing and reduces friction between the cylinder and piston.

Final Inspection

After the process is complete, a final inspection is conducted to ensure that the desired surface finish has been achieved. This step is critical in guaranteeing the effectiveness of the honing process in enhancing the hydraulic cylinder’s performance.

Benefits of Hydraulic Cylinder Honing

Improved Seal Performance

Honing creates a smoother surface, reducing the likelihood of leaks and enhancing the effectiveness of seals within the hydraulic cylinder.

Reduced Friction

The honing process reduces surface irregularities, minimizing friction between the cylinder and piston. This contributes to smoother operation and increased overall efficiency.

Extended Component Lifespan

By eliminating imperfections and reducing wear, hydraulic cylinder honing helps extend the lifespan of the cylinder. This is particularly beneficial in high-performance and heavy-duty hydraulic systems.

Enhanced Performance

Honing contributes to the optimal performance of hydraulic cylinders by ensuring precise tolerances and a high-quality surface finish. This is crucial for applications where precision and reliability are paramount.

Cost-Affective Maintenance

This is a cost-effective maintenance technique compared to the expense of replacing cylinders. It allows businesses to refurbish and optimize existing components, promoting sustainability and efficiency.