What are 3 Types of Hydraulic Pumps?

When taking a look at hydraulic systems, there are typically 3 types that stand out. The three categories of pumps include gear, piston, and vane, other variants fall under one of these. They are a very critical part of industrial machinery and have the important job of converting mechanical force into fluid energy. Each different pump has a different use, and something that it specializes in.

Type of Hydraulic Pump #1: Gear Pump

The most commonly used Hydraulic Pump is the gear pump. Called a Gear Pump because it has two rotating gears that turn in the body of the pump. There are two kinds of gear pumps, internal and external which reflect how the system is set up. Internal gear pumps have two different-sized gears that interlock and move within each other. External gears have two of the same sized gears that interlock, reinforced by different shafts. It’s a simple and compact system that can be easier to fix compared to the other systems due to fewer parts.

Gear Pumps are often used in different industries to transfer a variety of high-viscosity fluids. They tend to be used in situations where specific dosages or high pressure is necessary. Output is also not affected much by the pressure which helps with irregular quantities. Some of the fluids used with hydraulic gear pumps…

- Chemicals

- Resin

- Oil

- Resin

- Ink

- Food Products

- Paint

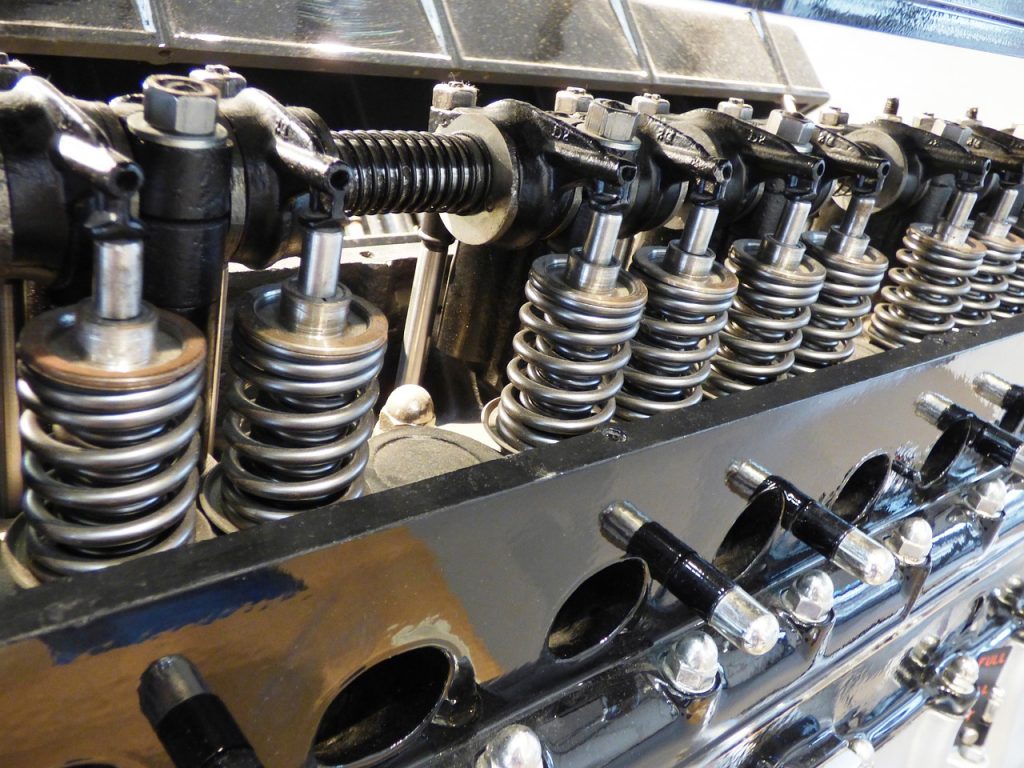

Type of Hydraulic Pump #2: Piston Pump

The Piston Pump is a more complex system and is found predominantly in the manufacturing world. There are also two main kinds of piston pumps Axial and Radial (there are others, but they are not as popularly used). The difference between the two is that radial piston pumps can be used with all kinds of fluids. Axial piston pumps are used more for their ability to handle high-pressure applications. Both the axial and radial have specific uses and should not be used interchangeably. Piston pumps are able to move liquids without the flow rate being messed up or decreased, they have a wide pressure range.

Axial pumps have a propeller like design that helps them push the flow of fluids in a spiral-like motion. Perfect for producing high flows of fluid and can handle a wide range of tasks.

Used For:

- Dewatering Floods

- Automotive Air Conditioning Compressor

- Construction Equipment

Radial pumps are able to push the flow of fluid outward after creating high amounts of pressure. They do an efficient job at making hydraulic power out of mechanical energy.

Used For:

- Energy Generation

- Power Steering and Braking

- Small Airplanes

Type of Hydraulic Pump #3: Vane Pump

Vane pumps have a smooth and low pulsation output and can pass thin liquids at high pressures. They have a robust and compact design while also being lightweight. Vane pumps can execute a steady flow while under different pressures. The pump’s vanes can also add or release tension so they can still reach the pumps walls no matter the viscosity of the liquid that is passing.

Vane pumps can offer a consistent flow pumping low to medium-viscosity liquids. Vane pumps also can be used to pump liquids as well as liquids containing solids. They have components that are hardened so that wear and tear takes longer to happen on the equipment.

Used For:

- Drink Dispenser

- Fridge Coolants

- Chemical Industry

Wrapping up the 3 Types of Hydraulic Pumps....

Taking in all of this information can be a lot to think about if you’re trying to figure out what pump is best. However, we may have a few questions to ask that may make it easier….

- What is the desired fluid flow rate?

- What kind of hydraulic fluid is used in the system?

- What kind of replacement costs are feasible?

- Maintenance Fees?

- What is the maximum operating pressure?

- High-pressure or low-pressure application?

Need some assistance answering these questions, or looking for a second opinion? All Phases can lead you in the right direction! Give us a call today and we can figure out what kind of hydraulic pump best fits your needs.

All Phase Hydraulics has various hydraulic pumps and motors that can work with any application equipment you might have. We are proud suppliers of hydraulic pumps and motors from Young Powertech Hydraulics & Dynamic Fluid Components.