What are Pnuematics?

Imagine a world where air becomes a mighty force that brings life to our machines and tools. That’s exactly what pneumatics is all about! In simple terms, pneumatics harnesses the power of compressed air or gas pressure to make things move and work. It’s like having a magic breath that brings life to everyday objects. This incredible technology finds its way into numerous industries, from engineering and manufacturing to construction and beyond. Pneumatics is the invisible hero that helps us build, create, and achieve remarkable feats with its invisible yet mighty touch. Let’s dive into the captivating realm of pneumatic systems and explore their fascinating applications!

How Do Pneumatics Work?

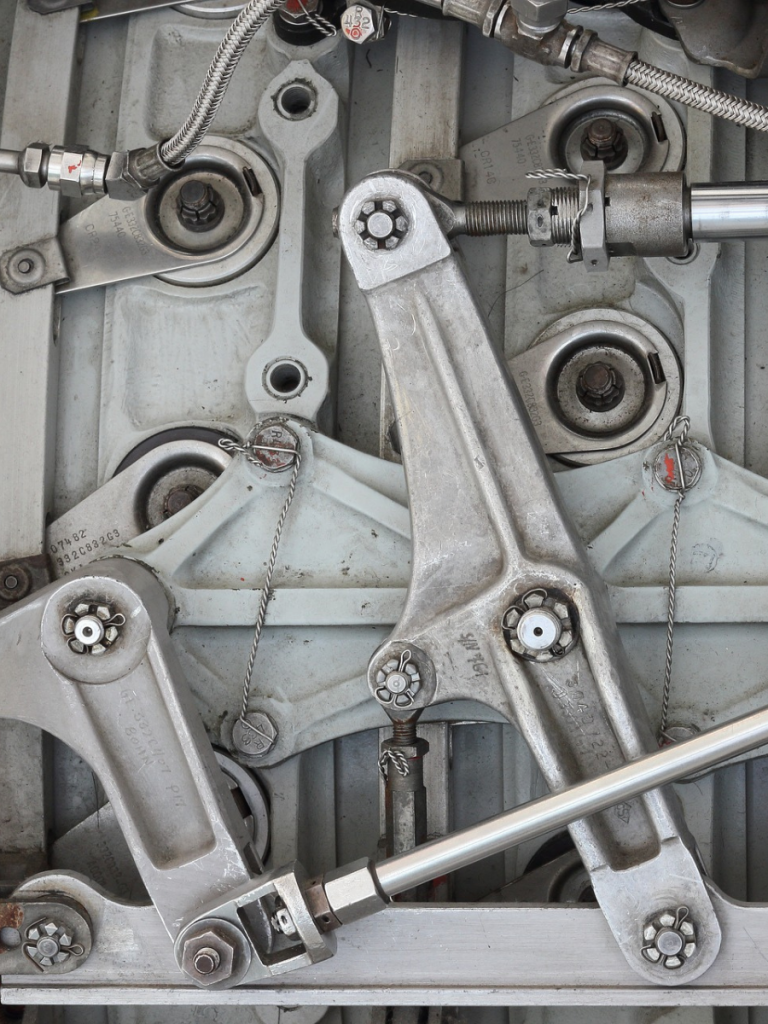

Pneumatic systems rely on the simplicity and reliability of clean, dry air to work. It all starts with an air compressor, which does the marvelous task of compressing the air, squeezing it into a smaller space, and increasing its pressure. The compressed air then enters a filter, ensuring that any impurities are removed, keeping the system running smoothly. From there, the air flows into pneumatic tubing, guided and controlled by valves that act as the conductors of this air-powered symphony. Finally, the air reaches the actuator, which is like the star performer of the show. This could be a cylinder, a device that moves back and forth, or a mechanism that carries out specific functions, such as lifting, moving, or gripping. The beauty of pneumatics lies in its simplicity and versatility, offering a powerful yet flexible way to bring motion and functionality to a wide range of applications.

How Do I Choose a Pneumatic System?

Pneumatic Systems can be used as an alternative to electric actuators and motors by driving linear and rotary motion applications. Pneumatic Systems differ from Hydraulic Systems as they use smaller loads and produce less force. Also, since air is easy to compress, pneumatics can absorb excessive shock.

As the manufacturing industry continues to make advances, and with developments in seals like corrosion resistance, the conditions in which pneumatics systems can be used has continued to increase. Pneumatics are such a versatile way to power tools and machinery, which keep them an important technology in a number of industries.

When selecting a pneumatic system, consider what you require in terms of your operating sequence. They work in a linear and rotary motion and is a simple way to activate an output motion or apply a force. You also should consider the pressure and flow requirements for the best possible performance.

Flow and pressure are different and should be controlled separately. The regulation of pressure in compressed air systems does not accurately control the flow, which could lead to an increase in energy costs. Whereas pressure is a force applied across a given area, the flow is the actual volume of compressed air being moved in a given time. Greater pressure over a small area can be the same as lower pressure over a larger area. Flow control works by restricting the orifice through which air can flow- as it closes, less air can flow, at a given pressure, in a given time.

Maintaining pneumatics and pneumatic systems is generally a low cost, but care should be taken to monitor leaks and corrosion. Also, by applying a filtration system and monitoring the air supply will also ensure your equipment to perform how it should.

Pneumatic Applications

Pneumatics are prevalent in commercial vehicles, the energy sector, including oil and gas and power generation industries, and food and beverage, from blow molding bottles through to process automation and packaging. They are also used across the manufacturing industry to power factory automation systems and is typically seen in sectors like materials handling and packaging. Some other examples are:

Transportations: Air brakes for trains or busses, air engines, and compressed air-powered vehicles

Healthcare: Dental drills, vacuum pumps, and pressure regulators

Construction: Pneumatic jackhammers and nail guns

Home Systems: Heating and air conditioning control

Music: pipe organs, player pianos.

Understanding Pneumatics and Pneumatic Systems is an important part of pertaining businesses and sectors. If you are looking for pneumatics or hydraulics, All Phase is here to help you out! Our dedicated and well-trained staff will learn about your needs and application desires to help pick out the right equipment for you!