Hydraulic Pump Issues and How to Fix Them

Hydraulic pumps are the unsung heroes powering many applications, from heavy machinery to industrial systems. These intricate devices are the lifeblood of many operations, enabling powerful movements and precise control. However, like any vital component, running into hydraulic pump issues will disrupt their seamless performance. Identifying and addressing these challenges is paramount to prevent downtime, productivity loss, and potentially costly repairs. In this blog, we delve into the realm of common hydraulic pump issues and provide you with practical insights and solutions. Whether you’re grappling with low pressure, worrisome noises, or leaks, we’ve you covered with expert guidance to keep your hydraulic systems running smoothly.

Low Hydraulic Pressure

When faced with low hydraulic pressure, your systems might exhibit sluggishness, reduced power, or erratic movements – clear signs that something isn’t quite right beneath the surface. A range of culprits could be at play, including worn-out seals allowing pressure to escape, pesky leaks sapping hydraulic power, or even a faulty relief valve failing to maintain optimal pressure levels. The good news is that addressing these issues isn’t rocket science.

Potential Solutions

- Checking and replacing worn seals, these can be major pressure leak sources

- Meticulously inspect the system for any leaks can often hide in plain sight

- Consider adjusting or replacing the relief valve, ensuring it’s calibrated to keep the pressure within the desired range

Following these steps will help restore your hydraulic system’s pressure and get things back on track.

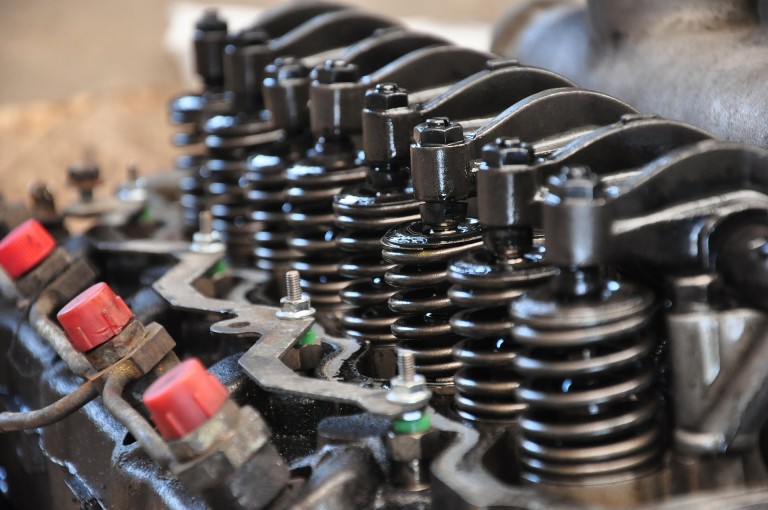

Excessive Noise and Vibration

When your hydraulic pump starts emitting unusual noises and vibrations, it’s like a distress call from the heart of your machinery. Groaning, rattling, or excessive vibrations can all signal underlying issues that demand your attention. These disturbances often arise from causes like cavitation – the formation and collapse of air bubbles within the fluid – or components that have seen better days due to wear and tear. Unbalanced loads can also contribute to the cacophony.

Potential Solutions

- Begin by inspecting the fluid levels to ensure they’re within the prescribed range

- Replace worn components and pay close attention to maintenance schedules to address these problems at their roots

- Balancing loads by redistributing weight can enhance your system’s stability, silencing those troubling sounds and vibrations

Overheating Hydraulic Pump

Hydraulic pump overheating isn’t just a minor inconvenience – it can pose a serious threat to your machinery’s health and efficiency. When these pumps become excessively hot, they suffer from reduced performance, increased wear and tear, and even catastrophic failures. This overheating often stems from root causes like insufficient fluid levels, where the pump lacks the necessary lubrication to function optimally, or contamination that clogs the system’s delicate pathways. Additionally, using the wrong viscosity fluid can exacerbate the problem.

Potential Solutions

- Regular fluid level checks and changing filters at recommended intervals can help maintain a cool operating temperature

- If the heat’s already on, consider adjusting fluid levels as well as

- Addressing contamination promptly saves your hydraulic pump from unnecessary strain

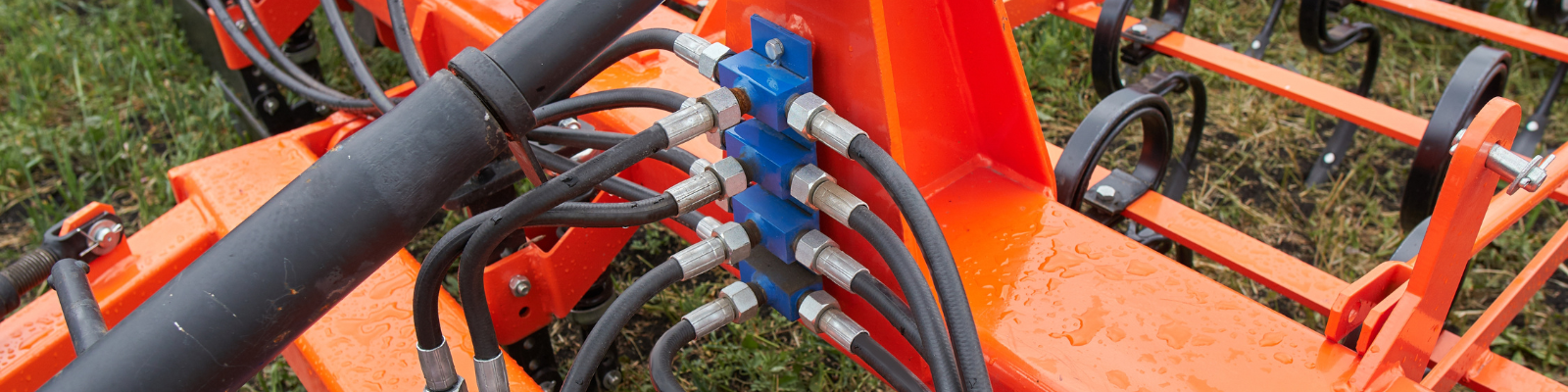

Hydraulic Pump Leaks

Leaky hydraulic systems can be a headache, with fluid seeping where it shouldn’t and performance taking a hit. There are several types of leaks to watch out for, from visible drips to stealthy seepages that evade the eye. These leaks are often traced back to culprits like damaged seals that have lost their tight grip, fittings that have grown too loose, or worn O-rings that have seen better days. Detecting these leaks is a crucial skill – keep an eye out for damp spots, oily residue, or even drops on the ground beneath the system. When a leak is spotted, it’s time to roll up your sleeves.

Potential Solutions

- Replacing worn-out seals and O-rings is a must

- Don’t forget to tighten any loose fittings that could be contributing to the issue.

Cavitation

Inconsistent pump performance can be a frustrating puzzle, as your hydraulic system seems to have a mind of its own. Trapped air bubbles in the system can disrupt the smooth flow of fluid, leading to irregular operation. Worn-out components can also be the culprits, as their diminished efficiency affects the overall system performance. And, of course, the pump itself might be the source of the issue due to malfunction or wear. Luckily, there’s a toolkit of solutions at your disposal.

Potential Solutions

- Bleeding the air from the system can often restore steady operation

- Replacing worn parts can rejuvenate the system’s functionality

- In more severe cases, repairing or replacing the pump might be the ticket to consistent performance once again

Contamination

When your hydraulic pump seems to be moving at a snail’s pace, it’s a clear sign that something’s amiss within your system. Slow pump operation can stem from a variety of underlying issues that hinder its efficiency. Contaminated hydraulic fluid, laden with particles or debris, can create sluggishness in the system. Contamination is a very common issue when it comes to hydraulic pump operation. Dirt, debris, water, and air can lead to wear and tear, impeding optimal performance. A malfunctioning pump, too, can be a culprit behind the lackluster pace. Rest assured, there’s a range of solutions to help you regain momentum.

Potential Solutions

- Inspect the system often

- Filtering or replacing the hydraulic fluid to rid it of contaminants can often breathe new life into your system

- Swapping out worn components can also revitalize the performance

- If needed, considering pump maintenance or replacement could put your system back on the fast track

Conclusion

Timely action when it comes to hydraulic pump issues isn’t just a matter of convenience – it’s a safeguard against potential disasters. Ignoring these problems can escalate into more extensive damage, resulting in downtime, costly repairs, and even compromised safety.

Regular maintenance and vigilant inspections act as a shield, catching issues early on and preventing them from snowballing into major concerns. Remember, you don’t have to navigate this alone. If you’re ever unsure or encounter complex problems, seeking professional assistance is a smart move.

Our aim with this blog was to equip you with insights and solutions to tackle common hydraulic pump challenges head-on. Here’s to smoother operations, reduced downtime, and a more efficient and reliable hydraulic system.